The customisation of the Aircraft Condition Monitoring System (ACMS) Database provides powerfull tools to monitor the system degradation of the aircraft pneumatic system. The following example has been implemented on Boeing 737NG aircrafts. The aircraft require additional sensors for system duct pressures and precooler outlet temperature (B737NG Line Number 3181 and following or implementation of Boeing Service Bulletin 737-26-1021).

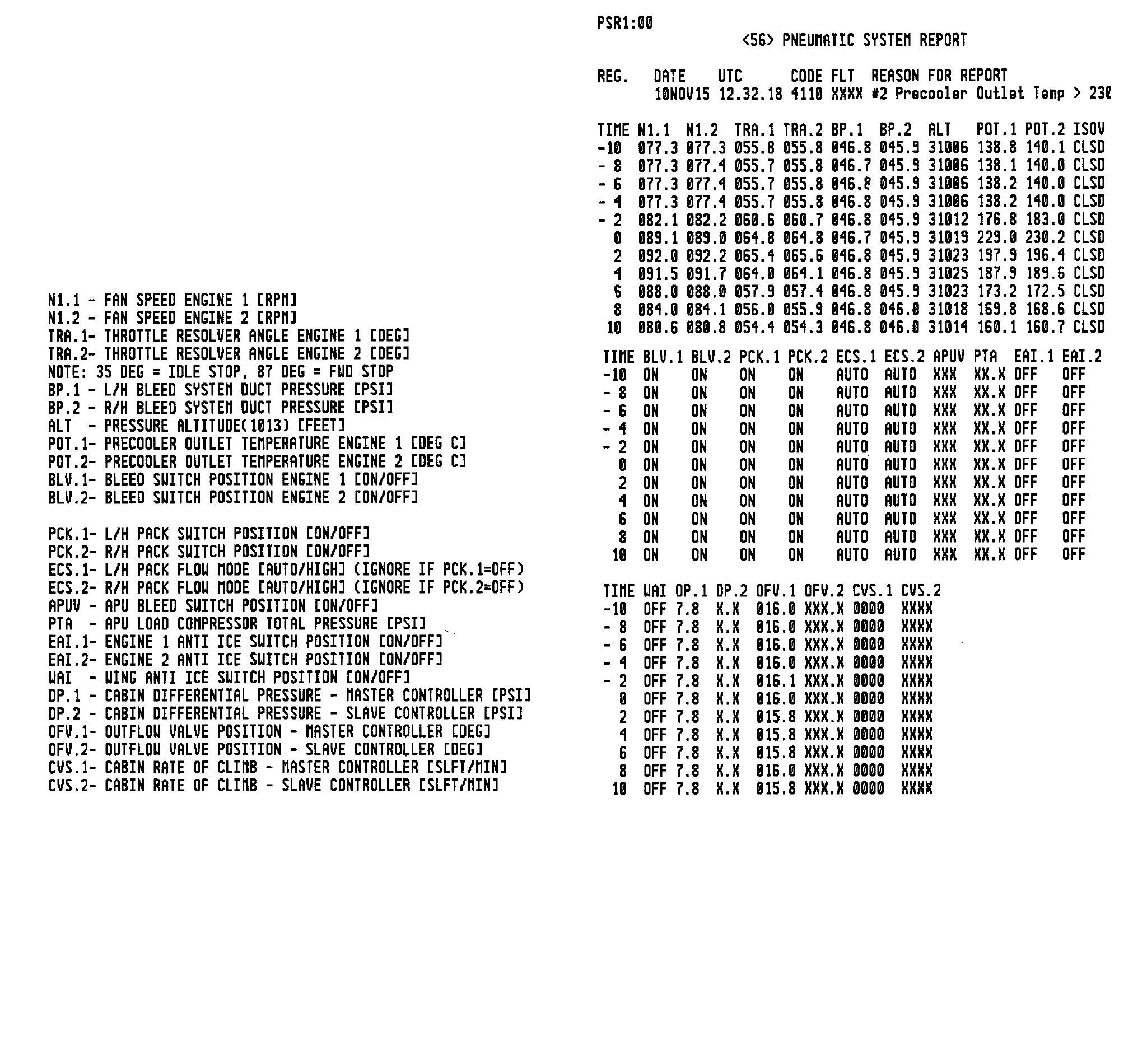

The ACMS system is able to generate reports, which provide usefull information to support the pneumatic system troubleshooting. The Boeing Fault Isolation Manual 36-10 together with Boeing Service Letter 737-SL-36-024 provides the guideline to perform the troubleshooting. Increased Precooler Outlet Temperatures, Low System Duct Pressures (including Duct Pressure Split) are not always recognized by the cockpit crew. The parameters are consistently monitored by the ACMS software and the following report format is generated, when a parameter is leaving the normal envelope:

The pneumatic system report can be printed in the cockpit or can be transmitted via ACARS to the airline operational control center. As an additional information source the ACMS system provides Smart ACMS Recorder (SAR) channels, which can be configured, to record various aircraft parameters in ARINC 429 format. This way the system behaviour can be analysed in a longer time frame.

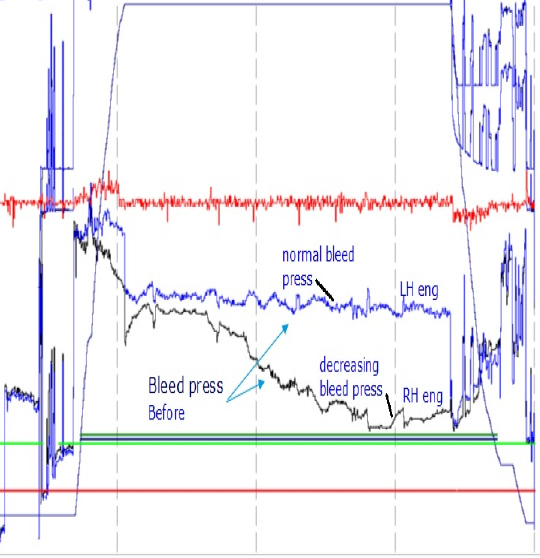

Example of the pneumatic system duct pressure recording showing a duct split in cruise flight.