The Aircraft Condition Monitoring System (ACMS) allows the implementation of advanced engine vibration monitoring functions. The following examples have been implemented on CFM56-7B turbofan engines:

-

Tracking of Vibration Peaks (filtered by the AVM Signal Conditioner) sorted by N1 and N2 Vibrations

-

Detection of #3 and #4 bearing vibrations (Advanced AVM Signal Conditioner P/N 241-298-002-011/-015 only)

-

Remote Alerting by the Debris Monitoring System (DMS)

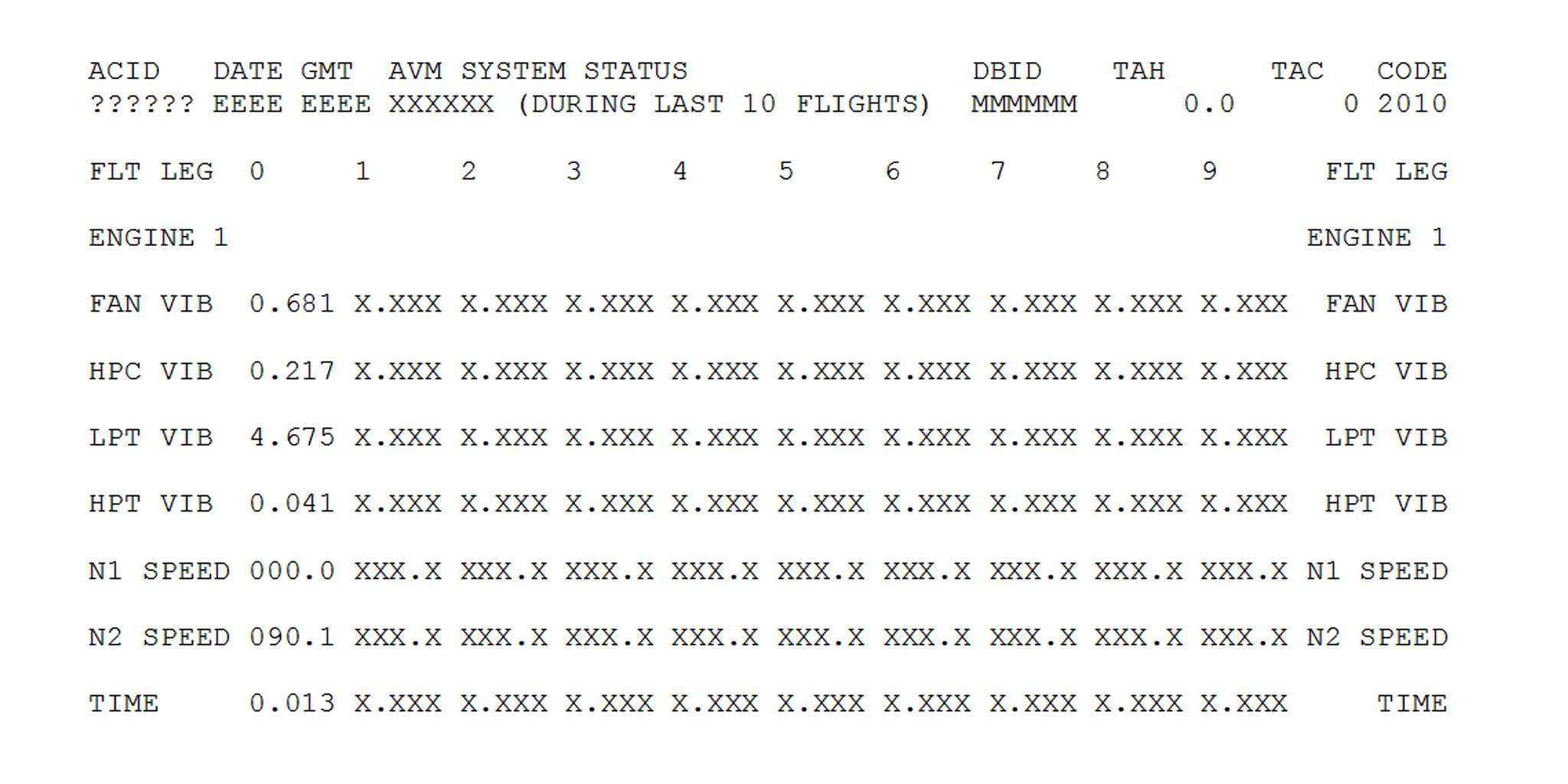

The tracking of the engine vibration peaks over a period of the last 10 flights can be done via an ACMS report, which can either be printed from the cockpit or downlinked via ACARS to the airline operational control center, if the vibration exceeds the normal status. The vibration data is divided into the following four sections:

- Fan Vibration (N1)

- High Pressure Compressor Vibration (N2)

- High Pressure Turbine Vibration (N2)

- Low Pressure Turbine Vibration (N1)

The algorithm detects the highest vibration (in scalar units) of all four sections of the engine during the whole flight and takes a snapshot of the remaining parameters. The vibration data are transfered to the next flight leg upon engine start.

The Vibro Meter Advanced AVM Signal Conditioner (AAVM) P/N 241-298-002-011/-015 is able to detect #3 or #4 bearing vibrations based on the CFM56-7B engine vibration signature. Two different firmware algorithms are in use by the AAVM to detect bearing vibrations:

- 1-ALGO – detects only vibrations of the #4 outer race bearing

- 3-ALGOs – detects vibrations of the following bearings:

- 4R – #4 outer race bearing

- 4L – #4 roller bearing

- 3B – #3 outer race bearing

The AAVM broadcasts the vibration data together with the current and historic maintenance levels on ARINC 429 labels 302 and 303 to the ACMS system. These data can be printed on an ACMS report or downlinked via ACARS to the airlines operational control center. Boeing Aircraft Maintenance Manual chapter 77-31-00 requires an inspection of the Magnetic Chip Detectors of the engine in case of an alert.

The FADEC system broadcasts the DMS status via the Display Electronic Units to the ACMS system through ARINC 429 label 271. The monitoring of the status of the magnetic chip detectors can be done from cockpit or remote from the home base using an ACMS report, which is downlinked automatically via ACARS.